What is EDM?

In the metalworking industry, EDM stands for “Electrical Discharge Machining,” a nonconventional method of metal removal utilizing an electrode to machine the chosen shape into a workpiece under tightly-controlled conditions. PH Tool employs both low-energy sinker EDM and ultra-fine wire EDM in our production facility. Over 50 of the 100+ machines in our facility are EDM workcenters, the balance being CNC mills, lathes, grinders, and other support equipment.

This method offers numerous advantages over traditional “chip making” machining, including:

- The ability to machine narrow notches and access hard-to-reach areas including pipe/tube IDs, without the need to section the workpiece

- The ability to hold extremely precise dimensional tolerances

- The ability to machine exotic alloys and hardened materials

- The ability to machine complex EDM features on irregular part geometries

- The ability to create extremely small-diameter holes with Depth:Diameter aspect ratios exceeding 100:1

- Our proprietary low-energy EDM technology ensures there is no adverse effect on material microstructure

Any conductive material is a candidate for electrical discharge machining. EDM notches can be machined on the outer diameter (OD) and inner diameter (ID) of pipe and tube. EDM allows for notches to be machined on IDs as small as 0.040" (1.0mm). Notches can be designed to match a contoured surface, ensuring uniform depth along the entire length.

Below you’ll find a list of standard EDM notch shapes that can be machined in virtually any location on any part you can imagine:

Basic EDM Notch Shapes

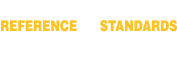

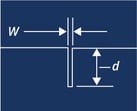

Square Notch – Otherwise known as the “buttress” notch, this notch has parallel-sided walls and minimal corner radius at the bottom. Typical of notches over 0.010" (0.25mm) wide. Square notches are available in depths from 0.0001" (2.50µm), widths from 0.010" (0.25mm), and lengths from 0.005" (0.13mm) through 12.000" (305mm).

Square Notch – Otherwise known as the “buttress” notch, this notch has parallel-sided walls and minimal corner radius at the bottom. Typical of notches over 0.010" (0.25mm) wide. Square notches are available in depths from 0.0001" (2.50µm), widths from 0.010" (0.25mm), and lengths from 0.005" (0.13mm) through 12.000" (305mm).

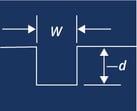

U-Notch – This notch features parallel-sided walls at the entry surface and a corner radius at the notch bottom that resembles a U-shape. Typical of notches under 0.010" (0.25mm) wide. U-notches are available in depths from 0.0001" (2.50µm), widths from 0.002" (0.05mm), and lengths from 0.005" (0.13mm) through 6.000" (152mm).

U-Notch – This notch features parallel-sided walls at the entry surface and a corner radius at the notch bottom that resembles a U-shape. Typical of notches under 0.010" (0.25mm) wide. U-notches are available in depths from 0.0001" (2.50µm), widths from 0.002" (0.05mm), and lengths from 0.005" (0.13mm) through 6.000" (152mm).

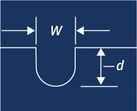

V-Notch – This notch has angled side walls that meet at the notch bottom, forming a V. Typical angles (a) for this notch type are 40, 45, 60, 70, 75 and 90°, with 60° being the most common. Available in depths from 0.002" (0.05mm), and lengths from 0.020" (0.51mm) through 3.000" (76.2mm.)

V-Notch – This notch has angled side walls that meet at the notch bottom, forming a V. Typical angles (a) for this notch type are 40, 45, 60, 70, 75 and 90°, with 60° being the most common. Available in depths from 0.002" (0.05mm), and lengths from 0.020" (0.51mm) through 3.000" (76.2mm.)

Nano Notch – The absolute narrowest notch available today. Widths start from 0.0006" (15.0µm), depths from 0.0001" (2.5µm), and lengths from 0.005" (0.13mm) through 1.000" (25.4mm). Some depth limitations may exist, depending on alloy and configuration.

Nano Notch – The absolute narrowest notch available today. Widths start from 0.0006" (15.0µm), depths from 0.0001" (2.5µm), and lengths from 0.005" (0.13mm) through 1.000" (25.4mm). Some depth limitations may exist, depending on alloy and configuration.

We hope this piece has helped to clarify available notch configurations. These are just some of the many possibilities that exist for EDM-machined features. To learn more about Nano Notches and other EDM possibilities, contact PH Tool Technical Sales.

For more than 40 years, our team of toolmakers, machinists, and management staff has supplied the NDT industry with high-quality test blocks and reference standards, featuring our EDM notches, flat-bottomed holes, and other "perfect imperfections."

We’ve spent decades earning a reputation for supplying our customers with products and services that are second-to-none. We look forward to answering your questions and teaming with you on your next project.

.jpg?width=759&name=edm%20blog%20photo%2012-2017%20(1).jpg)