PH Tool

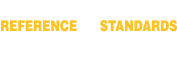

PH Tool offers many different types of holes used in NDT today. Of these different hole types, the flat-bottom hole (FBH) is by far the most commonly made. The FBH is king in the ultrasonic testing world due to the simple fact that it is excellent at reflecting sound directly back at the transducer. They provide a perfect “disc-shaped,” planar reflector that can be used to set instrument sensitivity, evaluate resolution, and can be used for flaw sizing comparisons. It is also possible to create “distance amplitude” reference curves using a series of FBHs of the same size, drilled to different depths, or “area amplitude” reference curves using a series of FBHs at the same depth, but of varying diameters.

Topics: Flat-bottom holes

The Importance of Surface Finish when Making NDT Reference Standards and Test Blocks

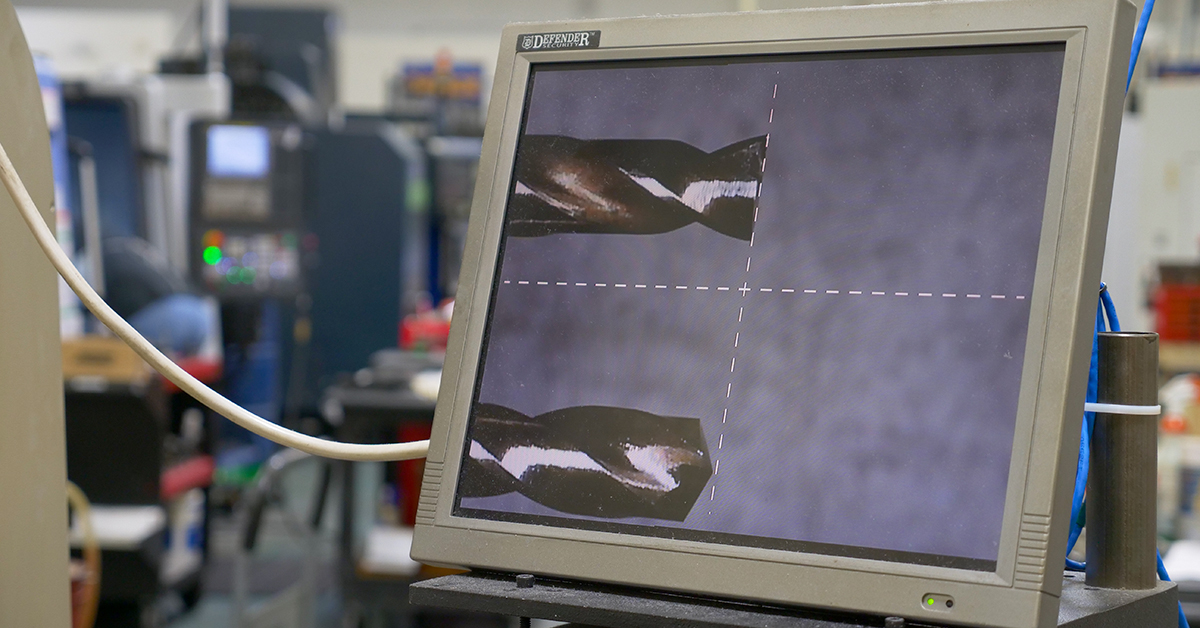

Surface finish describes the roughness or irregularity of a surface using a measurement system to quantify the results. This system covers a wide range from extremely rough-textured surfaces all the way to those that are highly polished, mirror-like surfaces. The predominant parameter is Roughness Average, denoted by “Ra,” which is the arithmetic mean deviation of a profile. The higher the number, the rougher the finish. Roughly milled surfaces will be in the 250 to 500 Ra µin (6.3 to 12.5 µm) range. Smooth surfaces machined by successive light passes on a surface grinder with flood coolant will yield finishes in the 16 to 32 Ra µin (0.4 to 0.8µm) range. The span of 16 to 500 Ra µin (0.4 to 12.5 µm) covers the majority of machined tools and parts in industry today. There are extremes beyond that range of course, but for purposes of Non-Destructive Testing (NDT) standards, they are rare.

Topics: Surface Finish, Roughness Average, Surface Roughness

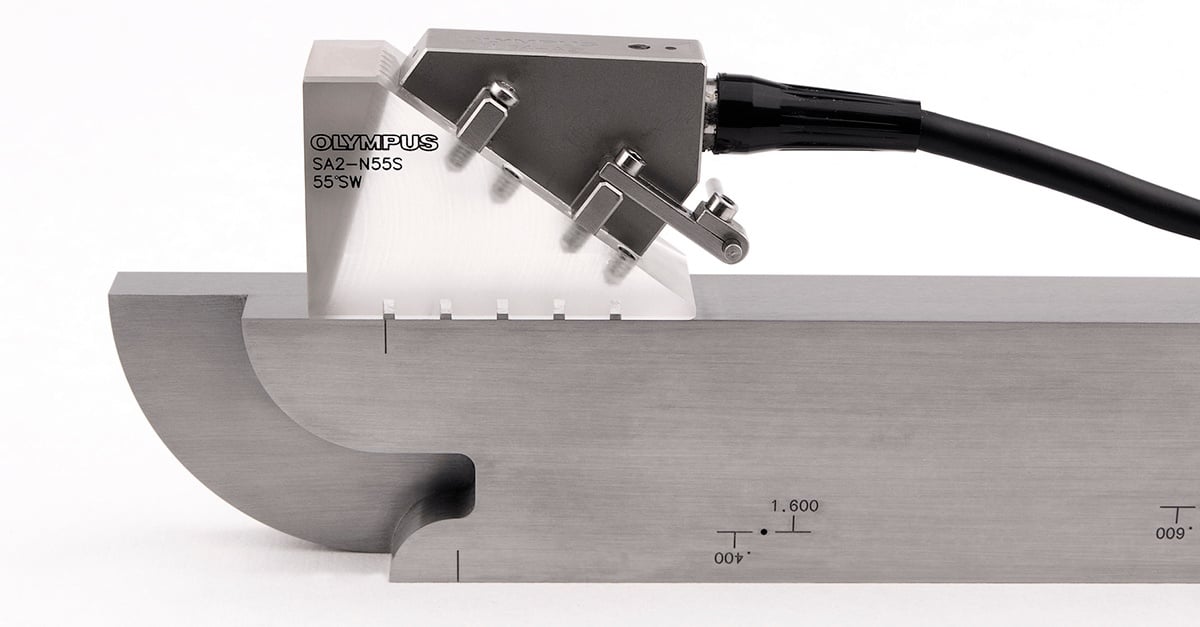

How Phased Array Ultrasonics Have Changed the Design of Test Blocks

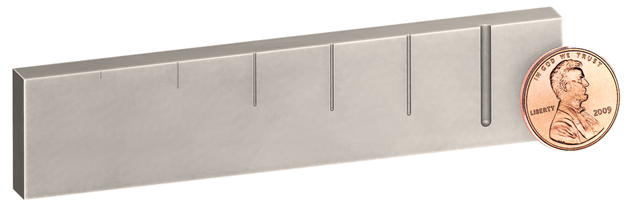

In the fast-changing Non-Destructive Testing (NDT) industry, Standard Test Blocks serve the very important purpose of standardizing and calibrating test equipment to ensure that it is functioning properly. These blocks are non-representative tools, meaning that they are not manufactured from, or machined to represent, actual parts. Rather, they consist of simplified design and contain manufactured targets such as side-drilled holes, flat bottom holes, angles, radii, steps and other geometric features.

Topics: phased array ultrasonic testing

What is EDM?

In the metalworking industry, EDM stands for “Electrical Discharge Machining,” a nonconventional method of metal removal utilizing an electrode to machine the chosen shape into a workpiece under tightly-controlled conditions. PH Tool employs both low-energy sinker EDM and ultra-fine wire EDM in our production facility. Over 50 of the 100+ machines in our facility are EDM workcenters, the balance being CNC mills, lathes, grinders, and other support equipment.

Topics: What is EDM?, EDM notch shapes

.jpg)